鋁製品

鋁製品

鋁製品

鋁製品

五金及金屬製品加工,五金製品,CNC/NC車床加工製品,車床/

沖床/沖壓加工,鋁製品

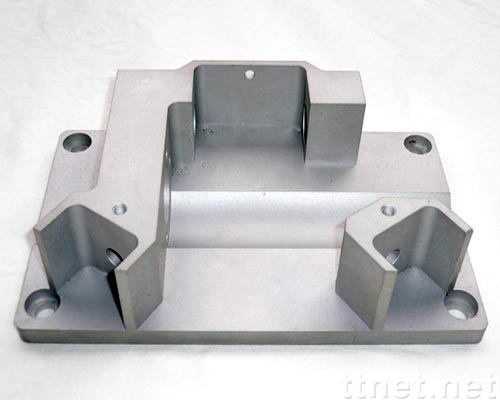

數控銑床用於加工鋁製品、五金和金屬製品。 該過程包括切割、鑽孔、開槽和攻絲。 該過程以高精度和高精度實施。 銑削工藝比其他傳統機加工工藝更高效、更快速。 它還能夠輕鬆生成複雜的形狀和設計。

鋁製品零件

鋁製品零件

鋁製品零件

五金及金屬製品加工,五金製品,CNC/NC車床加工製品,車床/

沖床/沖壓加工,鋁製品

鋁製曲面零件

鋁製曲面零件

鋁製曲面零件

五金及金屬製品加工,五金製品,CNC/NC車床加工製品,車床/

沖床/沖壓加工,鋁製品

鋁製品零件

鋁製品零件

鋁製品零件

五金及金屬製品加工,五金製品,CNC/NC車床加工製品,車床/

沖床/沖壓加工,鋁製品

鋁製品零件

鋁製品零件

鋁製品零件

五金及金屬製品加工,五金製品,CNC/NC車床加工製品,車床/

沖床/沖壓加工,鋁製品

鋁製曲面零件

鋁製曲面零件

鋁製曲面零件

五金及金屬製品加工,五金製品,CNC/NC車床加工製品,車床/

沖床/沖壓加工,鋁製品

鋁製品零件

鋁製品零件

鋁製品零件

五金及金屬製品加工,五金製品,CNC/NC車床加工製品,車床/

沖床/沖壓加工,鋁製品

鋁製品零件

鋁製品零件

鋁製品零件

五金及金屬製品加工,五金製品,CNC/NC車床加工製品,車床/

沖床/沖壓加工,鋁製品

鋁製品的全面探討:從特性到應用

鋁是地殼中含量豐富的金屬元素之一,因其獨特的性質,如輕質、防腐蝕和良好的導電性,被廣泛應用於各行各業。本文將詳細介紹鋁的特性、加工過程、應用範圍以及鋁製品在未來發展的趨勢。

一、鋁的基本特性

鋁的原子序數為13,是一種銀白色輕金屬,具有以下幾個顯著特點:

1. 輕質

鋁的密度大約是鋼的三分之一,這使得鋁成為航空、汽車等行業減重的理想選擇。

2. 高導電性

鋁的導電性僅次於銀、銅和金,使其在電線和電纜製造中非常有用。

3. 抗腐蝕性

鋁表面自然生成的氧化鋁膜可以防止內部金屬進一步氧化,從而提供良好的抗腐蝕性能。

4. 延展性

鋁極易加工成各種形狀,其延展性讓它在包裝和建築行業中有著廣泛的應用。

二、鋁的加工技術

鋁的加工涵蓋了從冶煉到成型的多個步驟,主要包括以下幾個階段:

1. 冶煉

鋁通常從鋁土礦中提取,經過拜耳法或霍爾-埃魯法處理,提煉出純度高的鋁。

2. 鑄造

液態鋁可通過鑄造進行成型,常見的鑄造方法包括壓鑄、連續鑄造和砂模鑄造等。

3. 軋製

鋁可以進行熱軋或冷軋,生產出鋁板、鋁箔等產品。

4. 拉伸和擠壓

鋁材可透過擠壓成型技術製造出各種截面形狀的鋁型材,廣泛用於建築和工業應用。

5. 表面處理

為了增強鋁的裝飾性或保護性,鋁表面可進行陽極氧化、塗層、電鍍等處理。

三、鋁製品的應用領域

鋁因其獨特的物理和化學性質,在多個領域中有著廣泛的應用:

1. 交通工具

在航空、汽車、鐵路和船舶製造中,鋁用於製造車身、發動機部件和結構元件,以減輕重量和提高燃油效率。

2. 包裝材料

鋁箔因其防潮、遮光和保質功能,是食品和藥品包裝的理想材料。

3. 建築材料

在建築行業,鋁型材被用於窗框、門、幕牆及其他結構元件,不僅美觀而且增強了建築的整體耐久性。

4. 電力和電子

鋁在電力傳輸線和電子裝置的散熱器件中的應用非常廣泛,尤其是在高功率設備中。

四、鋁製品的未來發展趨勢

隨著科技進步和環保要求的提高,鋁製品的開發趨向以下幾個方向:

1. 輕量化

隨著能源效率和減排壓力的增大,鋁在交通工具中的輕量化應用將持續擴大。

2. 循環利用

鋁是100%可回收的材料,未來將加大對廢鋁回收再利用的投資,以減少對原礦資源的依賴及環境影響。

3. 技術創新

新技術,如添加新型合金元素和改進的冶煉技術,將提高鋁材的性能,拓展其在高科技領域的應用。

4. 綠色製程

在鋁的生產過程中減少能耗和排放,使用更環保的生產技術和材料,將是未來發展的重要方向。

結語

鋁及其製品以其卓越的性能和廣泛的應用前景,已成為現代工業不可或缺的材料之一。隨著對鋁製品需求的不斷增加及科技的持續進步,鋁製品的發展將持續帶來新的機會和挑戰,引領多個行業邁向更高的發展階段。

CNC鋁製品:精密製造的未來

隨著現代工業技術的發展,CNC(Computer Numerical Control,電腦數字控制)技術在鋁製品的製造中扮演了越來越重要的角色。這篇文章將深入探討CNC鋁製品的製造過程、技術特點、行業應用,以及面臨的挑戰和未來發展趨勢。

一、CNC技術概述

CNC技術指的是利用電腦進行數字化控制的製造過程。在CNC機床中,工件的加工路徑和加工參數都是由電腦程式來設定的,這使得製造過程達到高度自動化,並能精確地重現高品質的鋁製品。

二、CNC加工鋁製品的優勢

1. 高精度與一致性

CNC技術能夠精確控制加工過程,保證每一個鋁製品都達到嚴格的尺寸和形狀標準。這對於航空航天、汽車及精密設備等行業尤為重要。

2. 靈活的設計適應性

CNC機床能夠輕鬆適應各種複雜的設計,使得鋁製品可以根據具體的應用需求進行個性化定制。

3. 高效率與節省成本

雖然CNC設備的初始投資較高,但其高效的加工速度和降低的人工成本使得大規模生產時更加經濟。

4. 減少材料浪費

CNC加工的精確度高,可以最大程度地減少原材料的浪費,對於成本控制和環保都有積極影響。

三、CNC加工鋁的應用範圍

1. 汽車行業

在汽車行業中,CNC鋁製品用於製造發動機部件、車身組件和各種結構部件,以減輕車輛重量並提高性能。

2. 航空航天

航空航天領域對材料的強度和重量有極高要求,CNC加工的鋁合金部件因其高強度和輕質化特性而被廣泛應用於飛機結構、發動機和內部組件。

3. 電子產品

在電子行業,CNC鋁製品常用於製造散熱器、機殼等,這些部件不僅需要精確的尺寸,還需要良好的美觀性和散熱性能。

4. 醫療設備

精密的醫療器械和部件也依賴於CNC技術來加工鋁材,確保器械的可靠性和安全性。

四、面臨的挑戰及未來發展

1. 技術創新

隨著市場對更高精度和更複雜產品的需求增加,CNC技術需要不斷創新,以提高機床的性能和多功能性。

2. 成本控制

儘管CNC加工有其經濟性,高質量的機床和維護成本仍是企業需要考慮的重要因素。

3. 技術人才

操作和維護高級CNC機床需要專業的技術人才,培養相關技術人才是推動行業發展的關鍵。

4. 環保壓力

隨著環保法規的加嚴,CNC加工業需要尋找更環保的生產方式,包括使用可回收的材料和減少生產過程中的能耗。

結語

CNC鋁製品因其卓越的性能和廣泛的應用前景,在全球製造業中占據了重要的地位。隨著技術的不斷進步和創新,CNC加工將繼續提升製造業的效率和質量,推動多個行業邁向更高的發展階段。

A comprehensive discussion of aluminum products: from characteristics to applications

Aluminum is one of the most abundant metallic elements in the earth's crust and is widely used in various industries due to its unique properties, such as light weight, corrosion resistance and good electrical conductivity. This article will introduce in detail the characteristics, processing process, application range and future development trends of aluminum products.

1. Basic characteristics of aluminum

The atomic number of aluminum is 13. It is a silver-white light metal with the following notable characteristics:

1. Lightweight

Aluminum is about one-third as dense as steel, making it ideal for weight reduction in industries such as aerospace and automotive.

2. High conductivity

Aluminum's electrical conductivity is second only to silver, copper, and gold, making it very useful in wire and cable manufacturing.

3. Corrosion resistance

The naturally occurring aluminum oxide film on the aluminum surface prevents further oxidation of the internal metal, thus providing good corrosion resistance.

4. Ductility

Aluminum is extremely easy to work into a variety of shapes, and its malleability makes it widely used in the packaging and construction industries.

2. Aluminum processing technology

Aluminum processing covers multiple steps from smelting to forming, mainly including the following stages:

1. Smelting

Aluminum is usually extracted from bauxite and processed through the Bayer process or the Hall-Herul process to extract high-purity aluminum.

2. Casting

Liquid aluminum can be formed by casting. Common casting methods include die casting, continuous casting and sand casting.

3. Rolling

Aluminum can be hot-rolled or cold-rolled to produce aluminum plates, aluminum foil and other products.

4. Stretch and squeeze

Aluminum profiles can be manufactured into various cross-sectional shapes through extrusion technology and are widely used in construction and industrial applications.

5. Surface treatment

In order to enhance the decorative or protective properties of aluminum, the aluminum surface can be anodized, coated, electroplated, etc.

3. Application areas of aluminum products

Aluminum has a wide range of applications in many fields due to its unique physical and chemical properties:

1. means of transportation

In aerospace, automotive, rail and shipbuilding, aluminum is used to create car bodies, engine components and structural elements to reduce weight and improve fuel efficiency.

2. Packaging materials

Aluminum foil is an ideal material for food and pharmaceutical packaging due to its moisture-proof, light-shielding and quality-preserving functions.

3. Building materials

In the construction industry, aluminum profiles are used in window frames, doors, curtain walls and other structural elements to not only look beautiful but also enhance the overall durability of the building.

4. Electricity and electronics

Aluminum is widely used in power transmission lines and heat sinks in electronic devices, especially in high-power equipment.

4. Future development trends of aluminum products

With the advancement of science and technology and the improvement of environmental protection requirements, the development of aluminum products tends to the following directions:

1. Lightweight

As pressure for energy efficiency and emission reductions increases, the lightweight application of aluminum in transportation will continue to expand.

2. Recycling

Aluminum is a 100% recyclable material. In the future, investment in the recycling and reuse of scrap aluminum will be increased to reduce dependence on raw ore resources and environmental impact.

3. Technological innovation

New technologies, such as adding new alloy elements and improved smelting techniques, will improve the performance of aluminum and expand its applications in high-tech fields.

4. Green process

Reducing energy consumption and emissions in the production process of aluminum and using more environmentally friendly production technologies and materials will be important directions for future development.

Conclusion

Aluminum and its products have become one of the indispensable materials in modern industry due to their excellent performance and wide application prospects. As the demand for aluminum products continues to increase and technology continues to advance, the development of aluminum products will continue to bring new opportunities and challenges, leading many industries to a higher stage of development.

CNC aluminum products: the future of precision manufacturing

With the development of modern industrial technology, CNC (Computer Numerical Control) technology plays an increasingly important role in the manufacturing of aluminum products. This article will delve into the manufacturing process, technical characteristics, industry applications, challenges and future development trends of CNC aluminum products.

1. Overview of CNC technology

CNC technology refers to the manufacturing process that uses computers to digitally control. In CNC machine tools, the processing path and processing parameters of the workpiece are set by computer programs, which makes the manufacturing process highly automated and can accurately reproduce high-quality aluminum products.

2. Advantages of CNC processing aluminum products

1. High accuracy and consistency

CNC technology can precisely control the processing process and ensure that every aluminum product meets strict size and shape standards. This is particularly important for industries such as aerospace, automotive and precision equipment.

2. Flexible design adaptability

CNC machines can easily adapt to complex designs, allowing aluminum products to be customized to specific application needs.

3. High efficiency and cost saving

Although the initial investment in CNC equipment is higher, its efficient processing speed and reduced labor costs make mass production more economical.

4. Reduce material waste

The high precision of CNC processing can minimize the waste of raw materials, which has a positive impact on cost control and environmental protection.

3. Application scope of CNC processing aluminum

1. Automobile industry

In the automotive industry, CNC aluminum products are used to manufacture engine parts, body components, and various structural components to reduce vehicle weight and improve performance.

2. Aerospace

The aerospace field has extremely high requirements on the strength and weight of materials. CNC-processed aluminum alloy parts are widely used in aircraft structures, engines and internal components due to their high strength and lightweight properties.

3. Electronic products

In the electronics industry, CNC aluminum products are often used to manufacture radiators, chassis, etc. These components not only require precise dimensions, but also require good aesthetics and heat dissipation performance.

4. Medical equipment

Precision medical devices and components also rely on CNC technology to process aluminum to ensure the reliability and safety of the devices.

4. Challenges faced and future development

1. Technological innovation

As the market demand for higher precision and more complex products increases, CNC technology needs to continue to innovate to improve the performance and versatility of machine tools.

2. Cost control

Although CNC machining has its economics, high-quality machine tools and maintenance costs are still important factors that companies need to consider.

3. Technical talents

Operating and maintaining advanced CNC machine tools requires professional technical talents, and cultivating relevant technical talents is the key to promoting the development of the industry.

4. Environmental pressure

As environmental regulations tighten, the CNC machining industry needs to find more environmentally friendly production methods, including using recyclable materials and reducing energy consumption in the production process.

Conclusion

CNC aluminum products occupy an important position in the global manufacturing industry due to their excellent performance and wide application prospects. With the continuous advancement and innovation of technology, CNC processing will continue to improve the efficiency and quality of the manufacturing industry, pushing many industries to a higher stage of development.